Products

Still struggling with the complexities? Want to achieve multiple variable distance transport operations at the same time?

According to conventional designs, more time, effort and cost must be spent. Complex designs, huge parts, high costs and tedious assembly ......

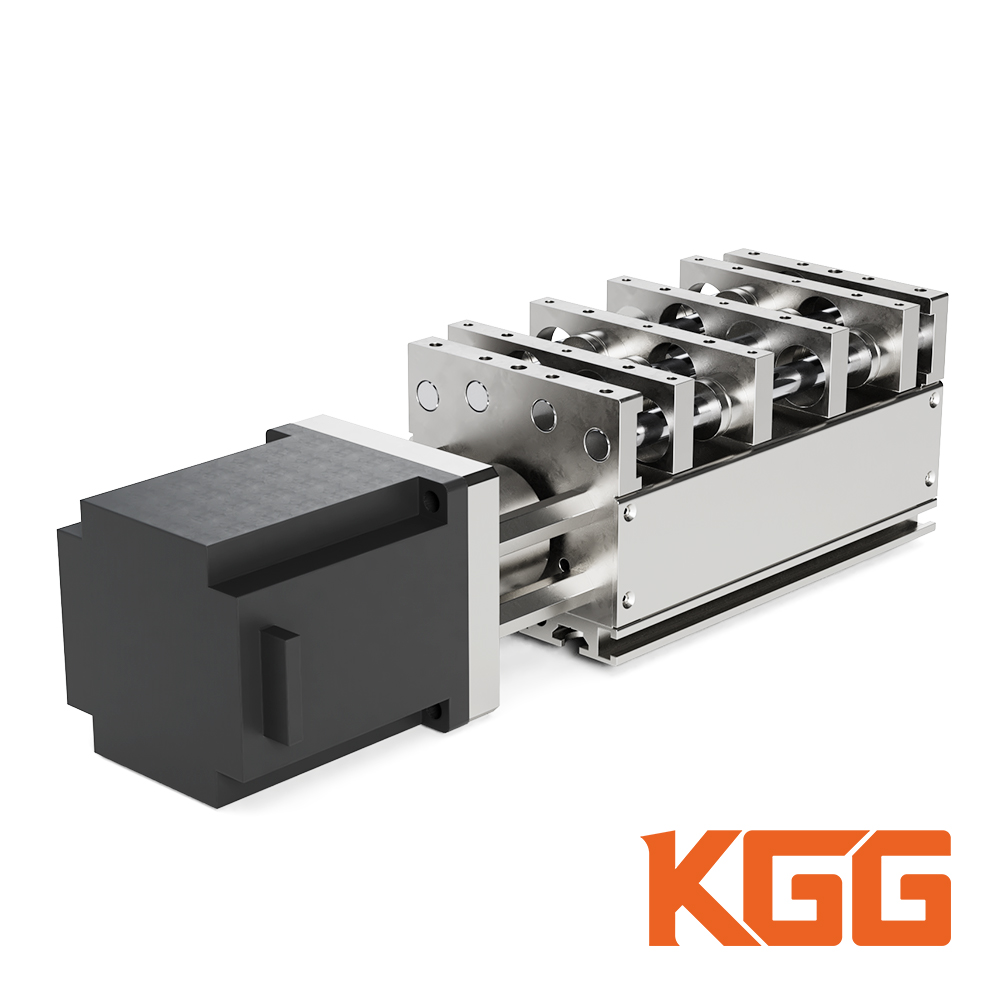

KGG PT pitch slide actuators can increase your productivity. The compact design reduces time in critical processes and enables up to 9 items to be picked and placed simultaneously with high precision pitch.

Here's What You'll Learn

As Featured On

Product Application

We look forward to your use of our products to add more cases!

Pipetting and Dispensing Workbench

PCB Drill Inspection

Semiconductor Packaging

SMT Machine

|

Model |

PT50 Type |

PT70 Type |

PT120 Type |

|

Width mm |

50mm |

70mm |

120mm |

|

Max. Length of the Body mm |

450mm |

600mm |

1600mm |

|

Maximum Numbers of Sliders |

12 |

18 |

18 |

|

Variable Distance Range mm |

10-51.5mm |

12-50mm |

30-142mm |

|

PDF Download |

* |

* |

* |

|

2D/3D CAD |

* |

* |

* |

|

If you need additional dimensions, please contact KGG for further review and customization. |

|||

Variable Pitch Slide Product Function and Operation Maintenance Instructions

1.Function Introduction:

This product uses a motor to control the variable pitch camshaft, achieving the required working conditions and set variable pitch positions. Installation and usage methods: horizontal,side-mounted, or inverted.

It is prohibited to use this product on a vertical axis. The spacing between each slider is constantly changing, and it is impossible to achieve independent movement of the sliding components. The change in spacing is adjusted by the rotation of the cam shaft (increasing or decreasing the motor pulse count). The input shaft can only rotate inward or outward in both directions and must be used within <324°.

2.How to Install:

3.Maintenance and Lubrication:

*Lubrication: Perform minor maintenance and lubrication every quarter.

Use a lint-free cloth to clean the sliding components and linear guides,and apply a small amount of lint-free oil to the track surface for maintenance.

*Cam Maintenance: Use an oil gun to apply a small amount of lubricating oil to the cam follower slots on each slider.(Recommended model: THK grease)

4.Precautions:

1.Pay attention to the installation at the bottom of the drawing, the depth of the pin holes and ensure that the pins are not too long to avoid piercing the profile material or causing the cam shaft to jam and damage.

2.Pay attention to the installation at the bottom of the drawing and the length of the screws. Screws must not be too long to avoid contacting the profile material.

3.When installing the belt pulley tensioner, do not over-tighten, as this may cause the camshaft to break.

*PT50 tension specification: 12N~17N.

*PT70 tension specification:32N~42N.

Note:

*If no tension gauge is available, after installing the belt, use two fingers to pinch the position indicated by the arrow in the figure and press the belt down by 4~5mm.

*If the belt cannot be pressed down by 4~5mm, it indicates that the belt tension is too high.

4. During electrical commissioning, strictly follow the camshaft rotation angle adjustment specifications specified in the drawings.

The maximum camshaft rotation angle should not exceed 0.89 revolutions(320°), to avoid collisions that could damage components).

You will hear from us quickly

Please send us your message. We will get back to you within one working day.

All fields marked with * are mandatory.

-

Top